ACP (Aluminum Composite Panel), often known as the sandwich panel, is a three-layered construction or cladding material that consists of a low-density core (thermoplastic polythene) and a thin skin layer (Aluminum or Rubber) attached to either side.

Aluminium Composite Panel are widely used in today's industries and other many fields which are related to design and ultra-modern style.

© Copyright Areca ACP Sheet - 2021

Aluminium Composite Panels

- Home

- Aluminium Composite Panels

The use of aluminium composite panels can be traced back decades. However, a tragic incident in 2017 - the Grenfell Tower fire in London — drew worldwide attention to this product. The old-style aluminium composite material used on the building's front was largely responsible for the fire's rapid spread.

This incident not only made the ACP sheet popular but also raised questions about its usability and safety. Nevertheless, following that incident, a number of measures were taken to lessen the risk associated with combustible cladding.

What Is an ACP Sheet?

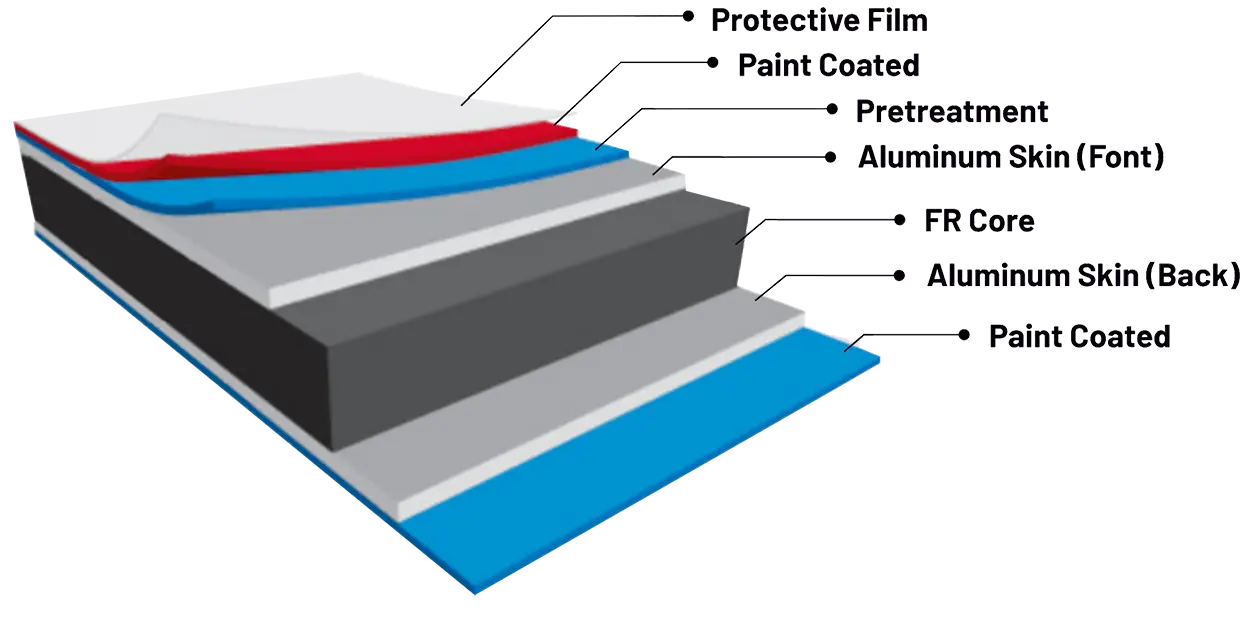

Aluminium composite panel, often known as ACP sheet, is a sandwich acp panel made up of three layers: aluminium sheet, FR Core, and aluminium sheet. In addition to these three primary layers, there are multiple more films and layers, such as protective film, paint coating, and adhesive layers, to name a few. All of these substances work together to make ACP an ideal robust building material that gives incredible strength to the structure.

Furthermore, the ACP sheet's stunning multiple finishes and surfaces make it suitable for both interior and exterior applications. Interior ACP panels, for example, can be used for interior walls, interior decoration, fall ceiling, wall panel, kitchen cabinet, modular kitchen, flash doors, partitions, and so on.

Likewise, exterior ACP panels can be used for a variety of applications such as commercial construction, beam cover partitions, signboards, multistory apartments, canopies, elevators, fake ceilings, spandrel panels, and display units, among others.

Moreover, these panels can be further classified based on their surface and application, such as partition panels, marble, mirror, and wooden ACP sheet, to name a few. In addition to interior and exterior aluminium composite panels, digital ACP panels are available too.

Why Choose ACP Sheets?

ACP sheets are one of the most flexible materials for cladding. It is popular among architects and designers, and the reason is justified! These sheets can reflect amazing designs and artwork that no other material can. Additionally, they are packed with a ton of features such as; durability, the ability to withstand environmental stress, ease of work with or installation, low maintenance, and so much more! The plethora of options available for ACP sheets in different colors, finishes, and textures when paired with the above-mentioned factors makes them an ideal option to go for.

Why Do We Use ACP Sheets As a Cladding Material?

As discussed, ACP sheets are incredibly durable and versatile, meaning they can blend in with every environment, and more importantly they can enhance visuals. These sheets are known to stand out in the crowd and provide a unique presentation of the installed structure. The flexibility of ACP cladding adds to its popularity, no other material can exhibit as much design as aluminum composite panels. Thus, making them a popular choice for designers and architects.

As a leading ACP sheet manufacturer, We earned a reputation by delivering such unique and trendy ACP panels in the market that resonate with the structures. Our sheets are available for exterior and interior purposes with a plethora of options to choose from such as; wooden, rustic, textures, solid colored and so much more.

Advantages of Aluminium Composite Panels

1. Lightness: Aluminum is a light yet sturdy element. It is known for its incredible strength for only a fraction of its weight. Therefore, ACP sheets are easy to install because of their lightweight design while offering incredible strength to the structure.

2. Versatility: ACPs can be used to display any type of design. These sheets are available in a wide array of designs and finishes. Innovation can be limitless when working with our sheets.

3. Durability: Aluminum is a strong element. Thus, aluminium composite panels can last for a long time without getting their designs and aesthetics compromised. Additionally, these sheets can withstand substantial amounts of environmental stress, thus, allowing them to last for a long time, especially for exterior applications.

4. Insulation: These sheets offer protection from sound and heat by acting as a barrier between the interior and exterior environment. This feature of ACP sheets is leveraged by commercial building owners to create a cool environment.

5. Resistive Nature: Aluminium composite sheets are anti-microbial, anti-fungal, dust-resistant, fire-resistant, and termite resistant. Essentially, cladding materials can be a pain to install, which is why durable and long-lasting materials are preferred that require less maintenance. Because of the resistive nature of these panels, they do not require reinstallation or regular maintenance! These sheets can continue delivering beautiful aesthetics with minimum effort.

Areca

Our Collections

ACP Sheet FAQ

Frequently Asked Questions (FAQ)

-

What is an ACP (Aluminum Composite Panel) sheet?

-

What is the price of an aluminium composite panel?The cost of the ACP sheet depends on several variables, including the material, size, texture, and quantity ordered. The most basic cost is roughly INR 55 per square foot, whereas premium sheets cost between INR 250 and 500 per square foot.

-

How many different types of ACP sheets are there?ACP sheets can be primarily divided into two categories: interior and exterior. However, we may also classify these sheets based on their surface and application. For example, marble, wooden, and digital finish panels.

-

What are the ideal qualities of an ACPs?The ideal qualities are eco-friendly, water-resistant, UV-resistant, exceptionally flat, flexible, and lightweight. Also, consider the company's reputation and customer service before you buy aluminium composite panel.

-

What is the standard ACP sheet size and thickness?The most popular sizes are 8x4 feet, 10x4 feet, and 12x4 feet. Whereas the thickness ranges from 1-6mm, with 3-4mm being the most common. However, you can always get a customized size based on your needs.

-

What does a typical aluminium composite panel made of?Aluminum Composite Panels have three layers. The core layer, made of polyethene, is sandwiched between two aluminum sheets under tremendous heat and pressure. However, depending on the requirements, the materials can be modified.

-

What are the applications of the ACP panel?ACP sheet is a modern building material that is mostly used for external and internal architectural cladding or partitions, false ceilings, facade, signage, machine coverings, modular kitchens, container construction, and so on.

-

Who is the top ACP sheet manufacturer in India?Without a doubt, Areca dominates the ACP panel industry in India with its stunning and finest-quality sandwich panels. The company offers a number of unique ACP collections that are tailored to specific applications and settings.